Dynamic Dies’s breakthrough, HD backing technology, is revolutionizing the industry. This high-durometer foam not only enhances print quality but also boosts efficiency and sustainability, making it a game-changer for businesses of all sizes.

The Challenge of Modern Corrugated Printing

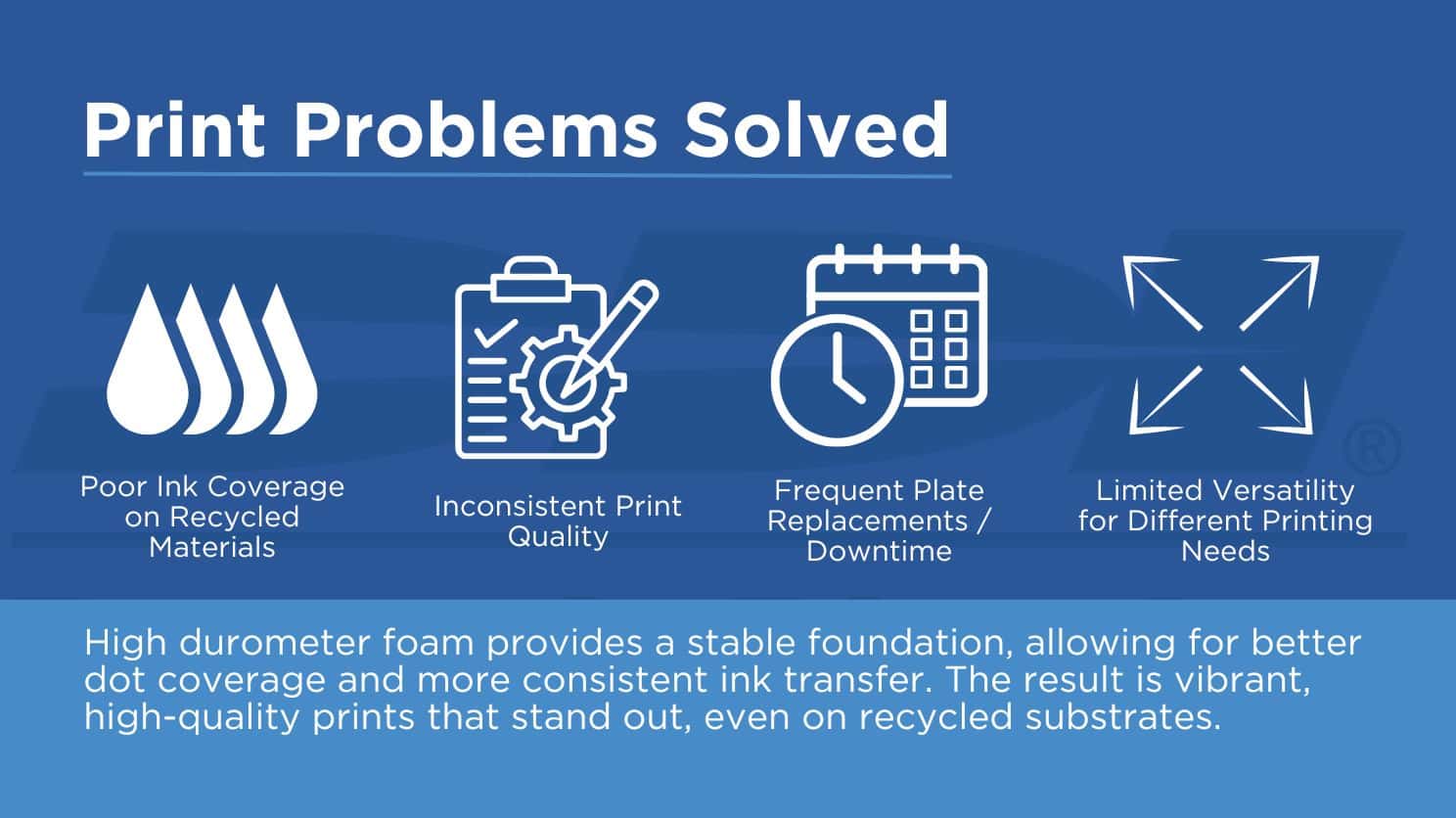

As the demand for faster production speeds and sustainable practices grows, the corrugated printing industry faces new challenges. One of the most pressing issues is the quality of recycled paper. The smaller and weaker fibers in recycled materials often result in poor ink transfer and coverage. Traditional printing methods struggle to achieve the vibrant, high-quality prints that customers expect.

What is HD backing and how does it differ from traditional foam backings?

HD backing stands for High Durometer foam backing. Unlike traditional soft foam backings, HD backing uses a harder foam that provides a stable foundation for printing plates. This results in better dot coverage, more consistent ink transfer, and superior print quality, especially on recycled materials.

The High Durometer Foam Solution

Dynamic Dies has tackled this issue head-on with their innovative HD backing technology. By replacing the traditional soft foams used for thinning printing plates with a high durometer foam, they have achieved remarkable improvements in print quality. This hard foam provides a stable foundation, allowing for better dot coverage and more consistent ink transfer. The result is vibrant, high-quality prints that stand out, even on recycled substrates.

Five Benefits of HD Backing

- Superior Print Quality: The hard durometer foam ensures excellent ink coverage, producing bright and vibrant colors. This is particularly important for customers who require high coverage, such as those using recycled corrugated materials.

- Enhanced Efficiency: With HD backing, printing plates can be built up more precisely, reducing the need for multiple adjustments and improving overall production speed.

- Versatility: This technology is not limited to high-speed presses. It is equally effective for smaller runs on older equipment, making it a versatile solution for a wide range of printing needs.

- Increased Durability: The high durometer foam backing enhances the durability of the printing plates, allowing them to withstand more runs and reducing the frequency of replacements. This leads to cost savings and less downtime for maintenance.

- Eco-Friendly Practices: By improving the print quality on recycled materials, HD backing supports sustainable practices within the industry. It helps to maximize the use of recycled paper, reducing the need for virgin materials and promoting environmental responsibility.

Custom Solutions for Unique Needs

Dynamic Dies prides itself on offering customized solutions tailored to each client’s unique needs. Their proprietary HD backing, developed in collaboration with DuPont, is a testament to this commitment. This exclusive product, combined with Dynamic Dies’ expertise, provides an unmatched competitive edge in the industry.

Beyond providing top-tier services, Dynamic Dies is dedicated to educating its customers. It offers detailed insights into the makeup and benefits of its HD backing technology, helping clients understand how to maximize its potential. This transparency and support foster strong, lasting partnerships.

Future in HD

As the printing industry continues to evolve, Dynamic Dies remains at the forefront of innovation. Their investment in advanced CDI units and ongoing research into new technologies ensures they are prepared for future developments. Whether it’s enhancing CMYK blends or adapting to digital printing trends, Dynamic Dies is ready to meet the challenges of tomorrow.

For more information on how our cutting-edge technologies can enhance your printing capabilities, visit Dynamic Dies or contact our team today.

Together, we can achieve exceptional results.

Key Takeaways

- Innovative HD Backing Technology: Utilizes high durometer foam for superior print quality and efficiency.

- Solves Major Challenges: Addresses poor ink coverage, inconsistent print quality, frequent plate replacements, and limited versatility.

- Key Benefits:

- Vibrant, high-quality prints.

- Increased durability of printing plates.

- Supports eco-friendly practices.

- Dynamic Dies’ Commitment:Continues to lead the industry with customized solutions and a strong focus on innovation and sustainability.

For more details, visit Dynamic Dies.